Biogas Process Information:

Types of Anaerobic Digesters

Process of Anaerobic Digestion

Process of Biogas Production

Sources of Biogas Energy

Biogas is produced by the chemical break-down of waste material containing high levels of fats, proteins, and carbohydrates. Anaerobic digestion of the process of breaking these waste materials down into biogas. Anaerobic digestion can be acommplished with three different types of digesters.

|

Plug flow digesters are typically long and rectangular in shape, however they can be built in a cylindrical shape as well. A block, or “plug” of high solids concentration (+13% solids) bio-waste manure is input into the inlet of the digester. |

|

Complete mix digesters are made for larger volume waste material and solid concentration of 3 to 10 percent. It can be either above ground or below ground. As the manure slurry is being digested, the mixture is continually mixed to make sure the solids remain in suspension. Large dairy farms use this style quite often. |

|

Animal waste manure is stored in a covered tank lagoon which traps all of the gas produced during the decomposition of the waste. Cover Lagoons are typically used with manure that has less than 3% solid concentrations. |

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

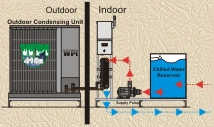

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |